By Ian Jackson VK3BUF. The original article was published in QTC January-March 2021.

Earlier in 2020 QRM Guru published an article to answer a few common questions on ferrite materials. It looked at budget versus expensive ferrite devices and plotted the results. The article also examined ways to extract the most benefit from your ferrite purchases. It can be viewed Here. The article attracted a lot of interest. We are now seeing more amateurs buying and fitting ferrite devices to reduce their local noise levels.

We received some correspondence from readers asking a couple of good questions, and we decided to put them to the test.

The first question was about thermal shock. If a balun or ferrite filter had too much power applied to it, would that heat shock also impair the ferrite core? Could a canny operator remove the melted remains and re-wind their balun with fresh wire, or was the core integrity forever compromised?

The second question came from operators who had ordered their nice big ferrite rings through the post, only to discover that they arrived shattered into many segments. It would not be difficult to super-glue the shards back into an original shape, so that the ring looked fine, but would it work as well as the original?

Perhaps the purchaser could make a warranty claim and try again, but the chance of it arriving in multiple pieces a second time is real! How well will a repaired ferrite function under actual RF conditions?

The third question asked about how ferrite rings can be applied. Sometimes we can’t get rings over existing plugs and cables. Can we simply loop the cable and pass rings over that loop. Would that be ok?

These were very practical questions, so at QRM.Guru we decided to perform the experiments and publish the results.

The first step was to select a pristine ferrite ring of a known material and benchmark its performance. We selected a thick ring 35mm in diameter, composed of Type 43 material.

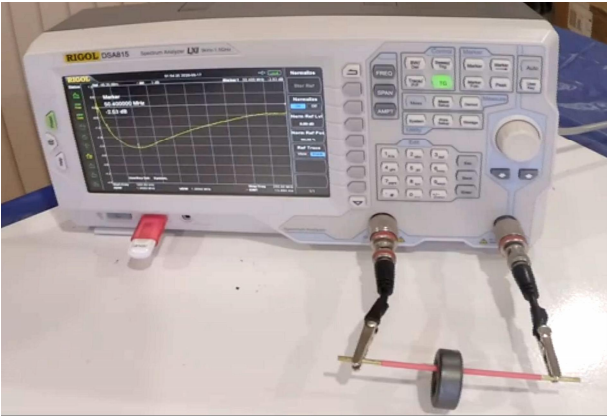

Next we set up a spectrum analyser and tracking generator as a test apparatus. This equipment consists of a receiver that scans the first 250 MHz of the radio spectrum, which is then coupled to a tracking signal source, which sweeps from 1 MHz to the same target of 250MHz. It performs this sweep perhaps ten times per second to give the viewer a steady picture. After the signal source is coupled to the receiver via a short brass rod, the display is ‘normalised’. This is a step where the receive signal is turned into a flat line across the screen, by compensating for other losses, such as the rod resistance and any stray capacitance values.

The idea is that when an unknown ferrite device is applied, it will add its unique absorption losses to the trace and we get a clear, stable ‘attenuation profile’ that is completely unique to that device. The trace is like a fingerprint showing how well a given ferrite performs over a 250 MHz range.

The characteristic curve of this brand new 35mm ferrite ring was saved to a memory stick for a later comparison.

Question 1: Does excessive heating destroy the ferrite?

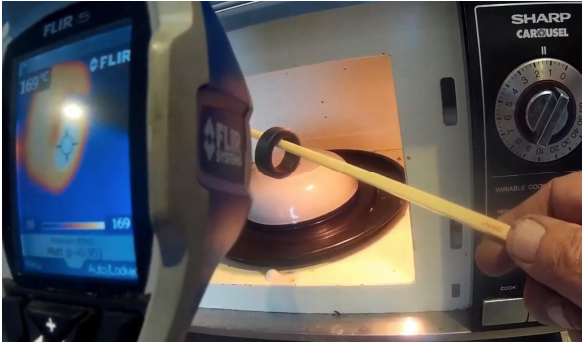

Having preserved the original profile, it was time to subject the ferrite ring to some extreme heat. The simplest way to do this was to place the ferrite ring in a microwave oven for a spell. As the ferrite material absorbs RF and dissipates the energy as heat, this old 500W oven would soon increase the core temperature of the ferrite ring.

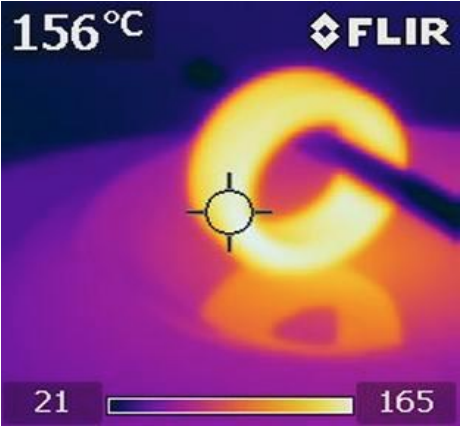

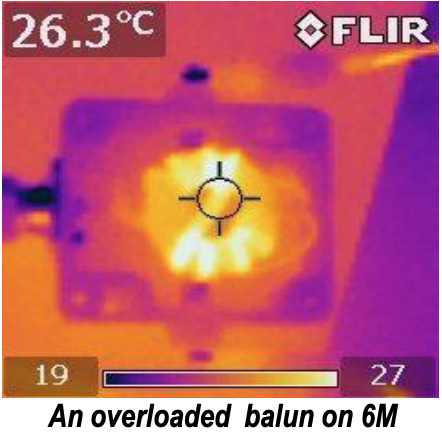

We used a handheld infrared camera to show what was happening to the ring over time.

After cooking it for several minutes, it appeared to plateau at around 170º C. As most electrical insulation is only rated to 105º C this session was more than enough to simulate the extreme abuse of a balun.

Once removed from the oven, it cooled down rapidly. Back at room temperature it was returned to the test area to see how it had been affected.

It appears that the ferrite core had endured a high temperature exposure without affecting its integrity, as its RF profile was unchanged.

Question 2: Does the ferrite still perform if it is broken and glued back together?

To resolve the second question of whether damaged ferrites can be repaired was going to require some drastic action. The ring had to be broken into several pieces. This could happen to any ferrite device that was poorly packed and subjected to abuse in transit. Similar damage could occur to a ferrite balun that had dropped from a tower after a storm. Ferrites are somewhat fragile and many Amateurs would have seen such destruction from personal experience.

We placed the ring into a small zip-lock bag so that no parts would be lost, then dropped it to concrete from approximately 1.2 metres above the ground.

It landed with a nasty crack and shattered after just one drop. A candidate for a rubbish bin. The problem is real. A larger ferrite purchased via from overseas could well be a $60 investment that arrives at your door in a similar condition.

The breaks in our ferrite were clean and the super glue made for a fairly solid repair, but would it still do what it is supposed to do, or was its efficacy lost forever?

With the ring reassembled, it was time to take it back to the analyser for one more test. Certainly some RF absorption of the core material would still take place, but how far from its original specification would the repair take it?

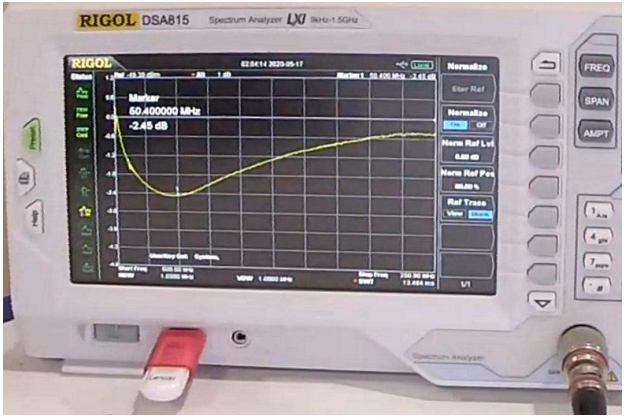

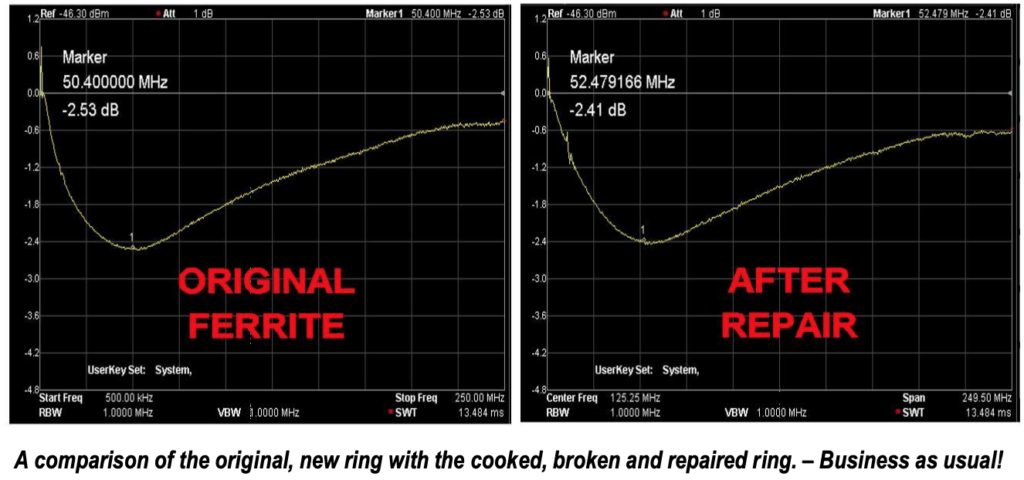

With a profile of any ferrite choke we would note the working bandwidth of the device and measure the frequency which yields the maximum attenuation. With our test ferrite we were only looking at the effects of a single pass of a conductor through the core, not multiple windings. This was intentional, as it removes the variability of copper windings from the experiment. It did mean that the absorption was not large. The original measurement peaked at around -2.5dB at 50.4 MHz.

With our first experiment the attenuation value did not change after the extreme heat test. It is safe to say that ferrite materials can withstand a lot more thermal punishment than the integrity of any wires that are wound through its core.

So yes to Question 1, you can recycle that fried balun with fresh wire and put it back into service. This is good to know.

As for the ring that was broken and repaired there was a tiny 0.12 dB reduction in attenuation and a slight frequency shift of 2MHz at its peak. These measured changes were so slight as to be insignificant. For Question2, yes if you can find all of the broken bits, it is certainly worthwhile glueing it together again and pressing it back into service.

Question 3: Instead of winding cable on a ferrite core, can we simply loop the cable and pass the core over that loop?

Question 3 was an important one. Wouldn’t it be great if a loop of cable could be passed through ferrite materials, without having to engage the services of an electrician?

Passing cables through a solid ring is not possible if both ends of an installation have been properly terminated by an installer. If this method worked, it would be particularly attractive to apply it to appliance cables and noisy solar panels!

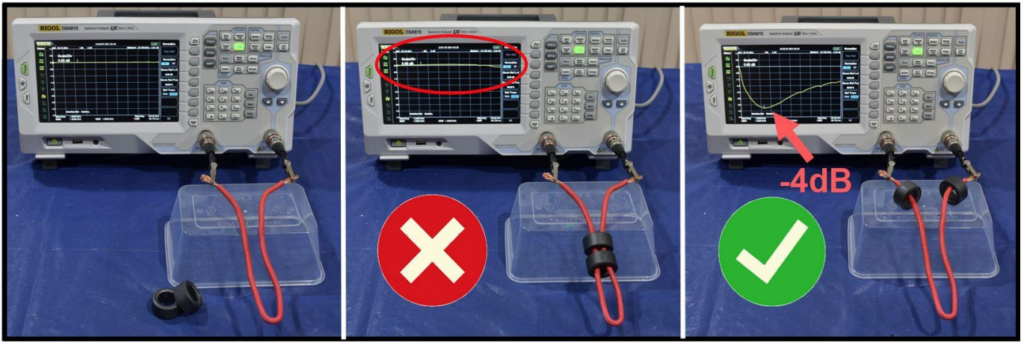

The short answer is NO. Don’t do it. The ferrites absorb very little RF energy when applied this way. It is easy to make a sweeping claim as to how ineffective it is to use ferrite devices this way, so we performed the experiment. Once again, we used the spectrum analyser and tracking generator for this work. The three images here tell the story. On the left, a short section of power cable was applied and its losses between 1MHz and 150MHz were normalised to a straight line.

The centre image shows that threading some ferrite rings over a loop in the cable had virtually no effect. The attenuation line (circled) was quite flat. In this configuration, the energy absorption characteristic of the ferrite materials are effectively cancelled out.

The third image shows the ferrite rings being fitted correctly, with the cable passing through each of the rings. A clear attenuation curve of -4db can be observed. Had the cable been passed through the ferrite devices two or more times, this curve would have been far deeper, but even this single pass showed a significant dip of absorption centred at about 25 MHz.

This simple study also highlights the usefulness of clamp-on ferrites. These clamps avoid having to remove any bulky connectors from any of the cable ends first. The convenience of easy application exceeds the cost of having to use several at each point to fully quash the noise.

In summary, ferrite materials have a powerful role to play in noise suppression and they can be very robust, but they have to be applied the right way or the effort is wasted. To view some of these experiments in video form, follow the link below to the QRM.guru website.