Discovering The Problem

Over the years, as we’ve continued to develop and improve our contest station here at SZ1A, one issue kept surfacing: the patch cables in our RF signal chain were a consistent point of failure. It wasn’t always obvious at first, a flaky SWR reading here, a sudden drop in signal strength there, but over time, the problem became unavoidable.

These symptoms were sometimes dismissed as antenna-related or blamed on propagation, but they kept reappearing, especially during high-power operation, after many hours in a contest or even after equipment swaps. It became clear that the problem was lurking somewhere else.

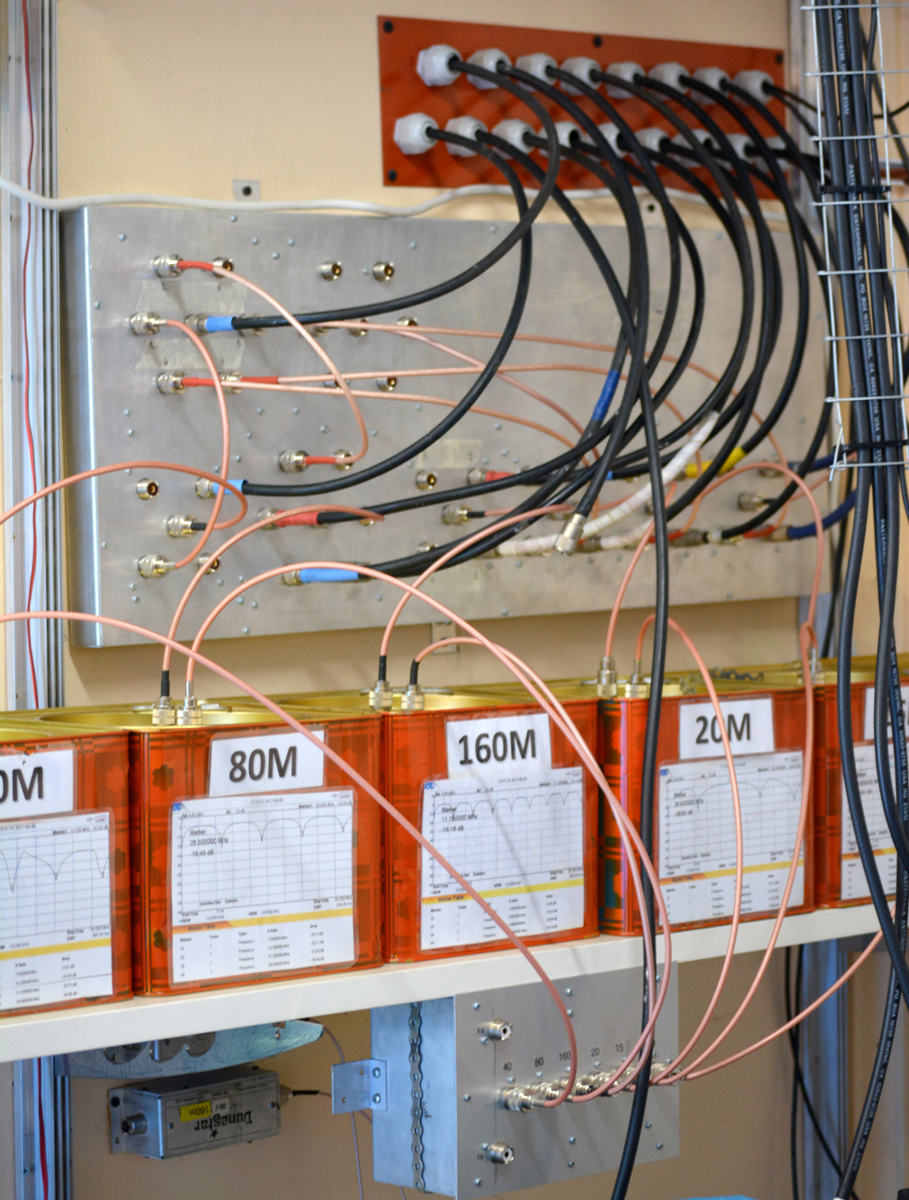

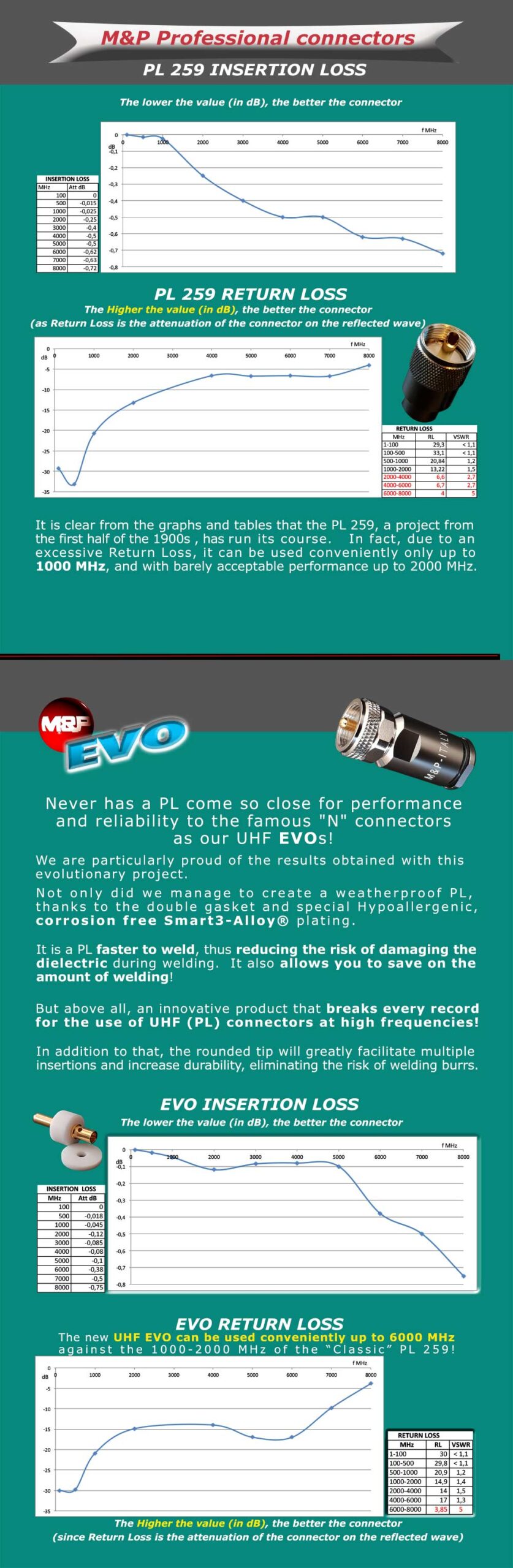

What triggered a serious investigation was our full station-wide technical evaluation earlier this year. As part of a broader NanoVNA-based filter and signal chain analysis project, we measured insertion loss and return loss across every segment in our RX and TX path.

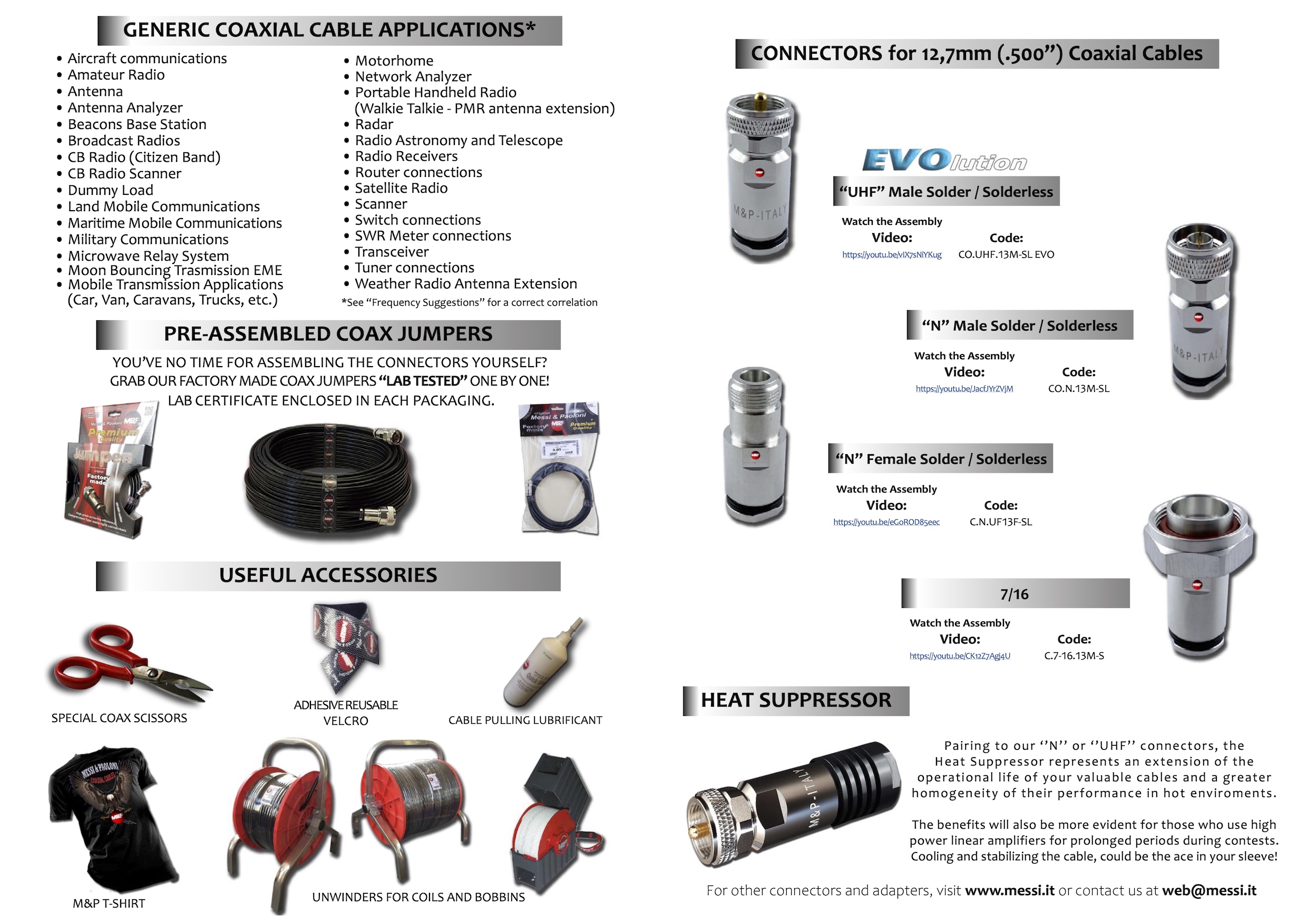

To our surprise (and frustration), some of our RG-400 jumper cables, which appeared visually intact, exhibited shocking performance inconsistencies.

These measurements weren’t just casual spot-checks. We documented every step and compared readings across identical cable lengths and routing paths, which made the anomalies even more obvious.

For example, we found 20 cm patch cables with losses as low as 0.015 dB… while others of the exact same length and from the same batch hit 0.3 dB or more!

To our surprise (and frustration), some of our RG-400 jumper cables, which appeared visually intact, exhibited shocking performance inconsistencies.

It might not sound like much, but that actually is an enormous loss, especially in a high-performance contest-grade station where every tenth of a decibel matters and where multiple patch cables are often needed due to complex RF switching. When the losses from each patch cable in series are combined, overall signal and power can drop by 50% or more if poor-quality components are used.

And the culprit was always the same: cheap, unreliable Chinese PL-259 connectors.

Connector Failures Under Pressure

Beyond the measured losses, we were also losing connectors to physical failure. We encountered cracked barrels, charred or loose pins, deformed and melted dialectric, center conductors that rotated freely, and, most concerning, loose connectors and structural failure after just a few cycles of high-duty cycle contest use. In a station that regularly runs 48-hour contests and pushes amplifiers to the legal limit, this level of fragility is simply unacceptable.

We found 20 cm patch cables with losses as low as 0.015 dB… while others of the exact same length and from the same batch hit 0.3 dB or more!

We also began to notice failures even under moderate conditions, particularly after repeated connect and disconnect cycles. Pins would lose solid contact, the threaded shell could bend or deform just from light finger pressure, and the dielectric often showed visible damage.

Several connectors showed signs of micro-arcing on the center pin, visible as blackened or pitted surfaces. These small imperfections can introduce minor impedance mismatches that compound into real-world performance degradation.

It became clear that we needed to either replace or rebuild all of our patch cables, ideally with high-quality, low-loss, high-power-rated connectors we could trust.

At this point, connector quality was no longer an afterthought – it had become a priority on par with filter and antenna performance.

Overall signal and power can drop by 50% or more if poor-quality components are used.

Exploring the Options: Amphenol, Competitors and M&P

We began by compiling a list of the most reputable connector manufacturers and reached out for quotes. Amphenol was an obvious candidate. It’s often considered the gold standard in RF connectors, especially in professional and military-grade applications.

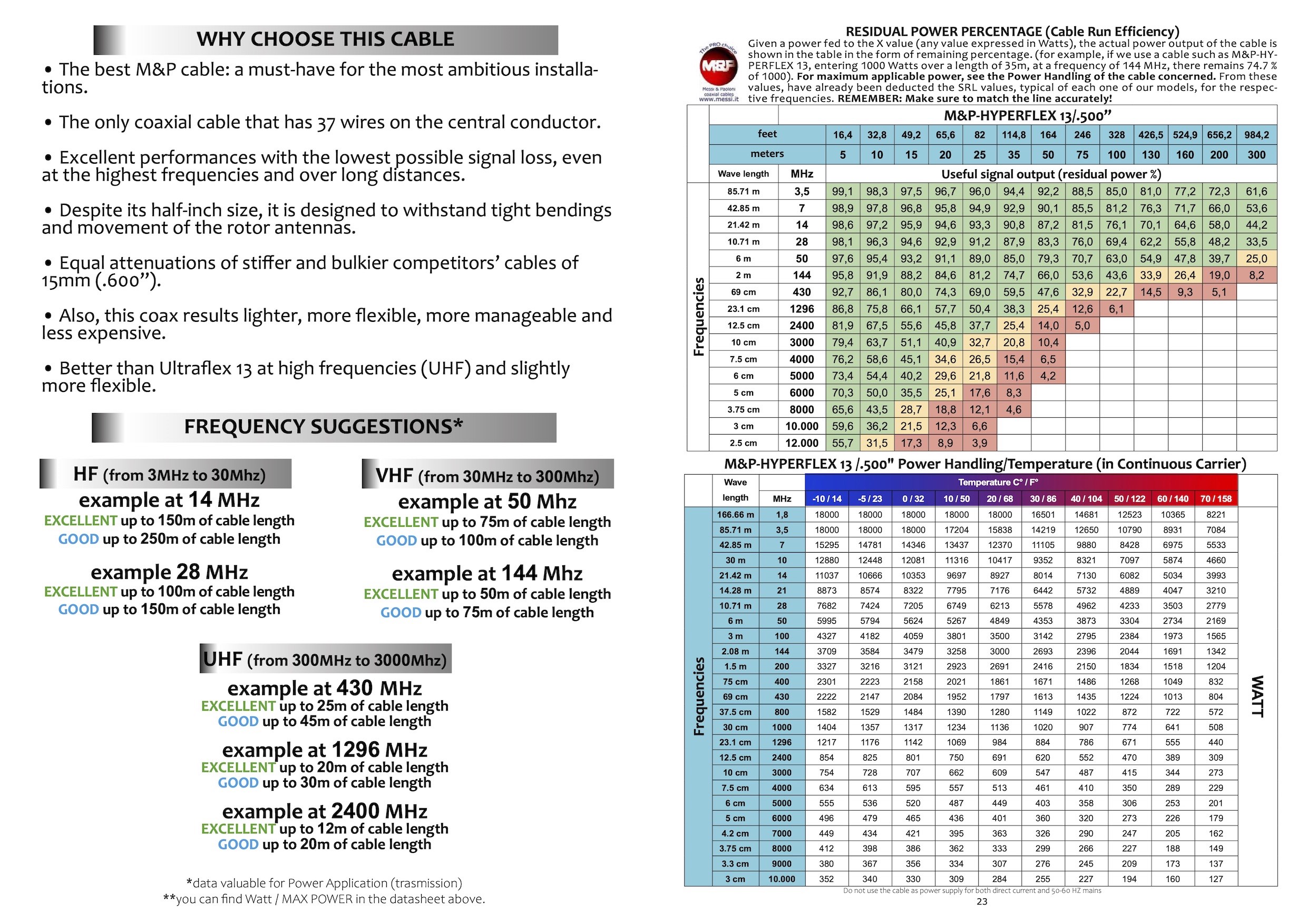

But we also looked into modern competitors and European suppliers — and that’s when we revisited Messi & Paoloni (M&P), whose products we had recently used with outstanding results during our tower and beam rebuild for the 20M band. Instead of installing the LDF4-50A 1/2 inch rigid Heliax we have in stock, we decided to purchase and install 55 meters of flexible Hyperflex-13 coax with M&P connectors for our 4-element monobander on the new 21m tower, and the results were impressive. VSWR and insertion loss were significantly better than our previous coax run, and the mechanical quality was top-tier. While we also didn’t need to splice in a flexible section for the rotator, further reducing complexity, cost and losses.

Encouraged by that experience, we sent out a custom quote request to multiple manufacturers and distributors, including M&P and their Greek distributor FreeBytes. Here’s a portion of the email we sent:

“At the moment, we’re using RG-400 patch cables with Chinese-made PL-259 connectors, but we’ve been facing consistent reliability issues — especially with connector failures under high power… We’re looking for high-performance, low-loss, and reliable jumper cables we can trust in a demanding contest environment.”

We specified the lengths and quantities needed, and requested certified VNA-tested assemblies. This wasn’t just about connectors, we were also evaluating the companies behind them. How quickly they responded, how specific their technical information was, and whether they understood our operating context mattered as much as the price.

It was important to us that any supplier understood we weren’t looking for generic, cheap off-the-shelf parts. We needed components that would hold up under repeated high-power use, across long contest weekends, with minimal drift or degradation.

At this point, connector quality was no longer an afterthought – it had become a priority on par with filter and antenna performance.

Reality Check: Price vs. Performance

The responses came in… and were sobering.

We reached out to several well-known suppliers of premium coax and connector assemblies, including DX Engineering and ABR Industries in America. Both companies responded with professional, detailed quotes that reflected significant discounts, especially considering the quantities we were after. However, despite the generous pricing, the total cost was still well beyond our budget.

Current import tariffs and shipping fees have pushed prices even higher, and the cost of materials like RG-400 coax and Amphenol PL-259 (83-1SP) connectors has skyrocketed recently. Even with club pricing and generous discounts, most quotes landed well above $1,500 (€1,400). Some even approached $2,500 (€2,300) before adding shipping and import duties.

Once all costs were factored in, the total would have exceeded $3,000 (€2,750) – which is far beyond what our station could justify for just 15 short patch cables.

To their credit, Messi & Paoloni and FreeBytes were the only ones who not only came in well below $1,000 (€850), but also offered generous amateur-friendly discounts exceeding 25%. While some of the other companies seemed to cater primarily only to large telecom or broadcast clients, both M&P and FreeBytes treated us like real partners, even though we are relatively small customers.

Even then, we had to make a tough decision: new, ready-made cables were just going to be too expensive.

We stepped back and re-evaluated what actually needed replacing. The cables themselves had tested well during our NanoVNA analysis, with consistent insertion loss and no visible damage.

The real issue was isolated to the connectors. Replacing only those would allow us to solve the problem at its source, without discarding perfectly good materials or overspending.

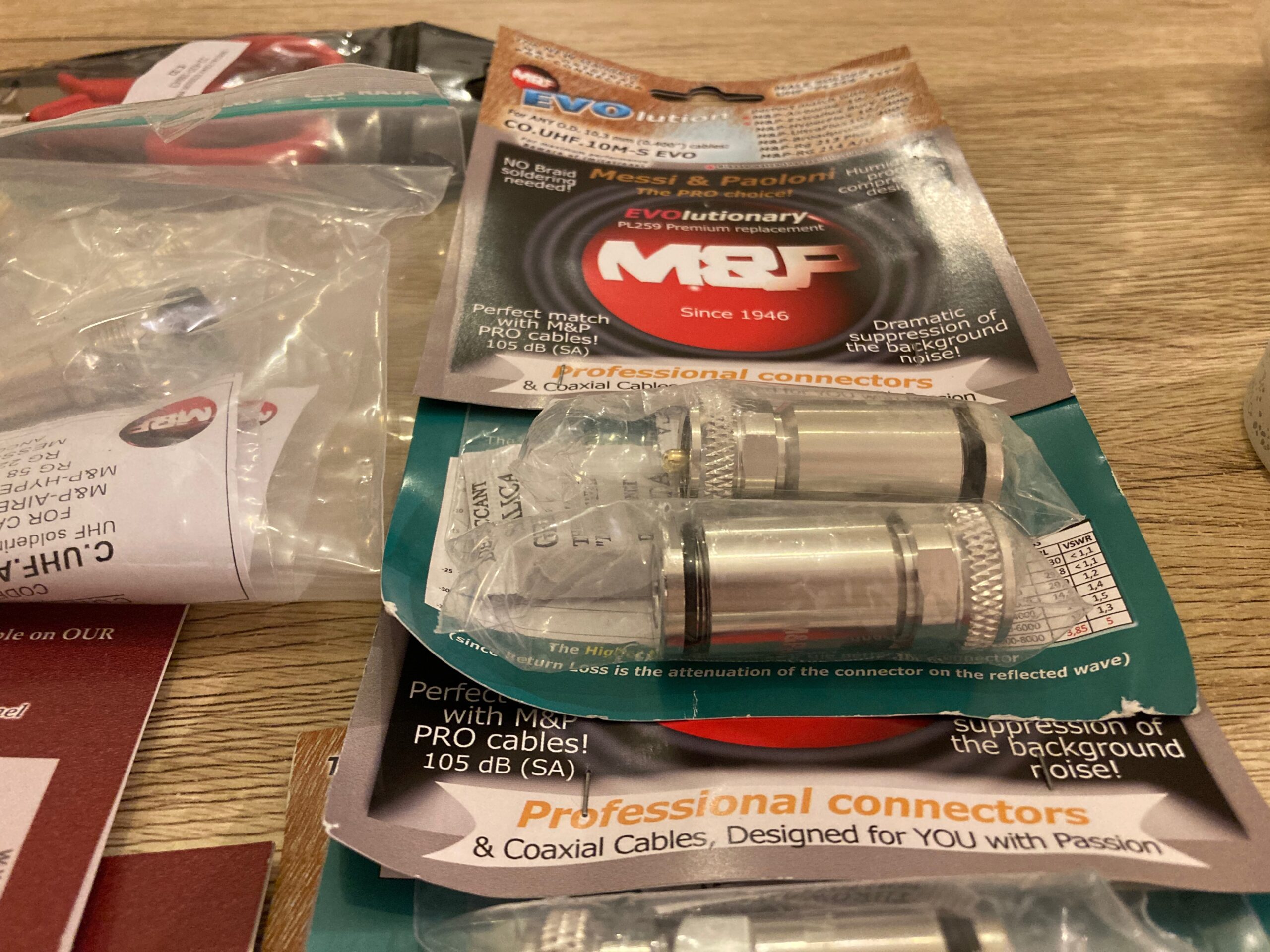

Instead, we chose a more budget-conscious but still high-performance path – we would keep the existing cables, but replace every connector with high-quality M&P EVO models.

This approach let us retain the good RG-400 we already had, which was still electrically sound, while upgrading only the weak points. It also meant we could control the soldering and assembly ourselves, ensuring clean terminations and verified performance using our own VNA before installation.

This method would also provide us the opportunity to standardize our connector terminations as much as possible. By using the same high-quality EVO models wherever possible, we would eliminate variability in connector performance, improve mechanical reliability, and ensure consistent impedance characteristics throughout the RF signal chain.

Ultimately, avoiding the extra costs of ready-made cables, their assembly, and their certification testing by the supplier would be the most effective use of our limited finances. We would handle the manual labour and testing ourselves, and, although it was a reluctant choice, we were confident that it was the most cost-effective one.

In high-performance contesting, every fraction of a dB counts

The Solution: What We Chose and Why

It wasn’t going to be easy, from selecting the right parts to replacing every connector across our patch cables. Each connection in our RF signal chain had to meet contest-grade standards, where even a fraction of a decibel lost at a connector could compound across the chain and affect both transmit punch and receive sensitivity.

M&P to the rescue!

Our priorities went beyond simple compatibility: the new connectors had to resist oxidation and mechanical wear in a demanding multi-operator contest environment, handle full legal-limit power without issue, and eliminate the unreliable solder joints and poor tolerances of the connectors we were replacing, while at the same time, as the highest priority, present near-zero insertion loss and excellent impedance characteristics of 50 Ω at HF and beyond.

With expert guidance from FreeBytes during the selection process, access to high-quality components, and a clear plan for resolving the issues affecting our station, we were ready to move forward. Here is what we ultimately ordered from Messi & Paoloni through FreeBytes, to rebuild our jumper cables and improve reliability, performance, and decrease losses across the RF signal chain, along with the purpose of each item:

🔧 SZ1A M&P EVO Connector Order Summary

Purpose: Rebuild jumper cables & improve performance across the RF signal chain

▶️ Connectors for Ø5mm (.200″) Coax (RG-400 etc)

- 30× EVO PL‑259 male

↳ For 15 RG‑400 jumper cables

Model: CO.UHF.5M‑S EVO

- 6× EVO SO‑239 female

↳ For building RG-400 high-power chokes (linears, lightning protectors)

Model: C.UHF.AC5F‑S EVO

▶️ Connectors for Ø10mm (.400″) Coax (RG-213 etc)

- 8× EVO PL‑259 male

↳ For longer patch cables (amplifiers to switches)

Model: CO.UHF.10M‑S EVO

▶️ Heat Suppressors

- 2× EVO Heat Dissipators for 10mm/.400″

→ For high-power amp outputs

Model: DISSIPATORE 10.3

▶️ Adapters

- 6× SO‑239 to SO‑239 barrel adaptors (female-to-female)

↳ For coax interconnects / patch panels etc.

Model: ADAPTOR UHF.F-UHF.F

- 2× PL‑259 to PL‑259 barrel adaptors (male-to-male)

↳ For quick-connect setups or spares

Model: ADAPTOR UHF.M-UHF.M

▶️ Tools & Accessories

- 4× Tubes of M&P Special Soldering Flux

↳ Residue-free, capillary-driven, high-strength soldering

Model: MP-FLUX2CC

- 1× M&P Special Coax Cable Scissors

↳ Clean, deformation-free cuts without dielectric damage

Model: FORB1

All parts belong to M&P’s EVO series, designed specifically for professional-grade RF environments. The connectors are robust, low-loss, and easy to work with. The SO-239 models even include two swappable shield inserts for different cable diameters, a detail we greatly appreciated, as tolerances may differ with various cables.

Choosing connectors with known performance characteristics and tight tolerances can eliminate many of the unknowns that cause frustrating RF issues in the field. These quality connectors help ensure predictable behavior when operating at high power or across wide frequency ranges.

Poorly machined or loosely fitting connectors can introduce intermittent contact, fluctuating impedance, or micro-arcing, all of which, as we have experienced, are hard to diagnose once installed.

By using quality connectors with documented specifications for insertion loss, return loss, and power handling, you reduce the risk of hidden faults and make it easier to isolate problems when they occur.

Additionally, using the right tools, such as non-deforming coax scissors and clean-burning flux, also plays an important role in ensuring proper terminations and long-term electrical stability. Tools like M&P’s coaxial scissors and high-quality flux aren’t just convenience items. Properly cutting coax without crushing the dielectric or fraying the braid helps maintain the cable’s impedance and shielding effectiveness.

This is especially important with cables like RG-400, where the PTFE insulation is slippery, and also for the less forgiving foam-type dielectrics that are in most modern coax cables, which can easily be deformed and damaged. Clean cuts and reliable solder flow reduce the chances of cold joints, RF leakage, thermal damage, or gradual performance drift over time.

Properly cutting coax without crushing the dielectric helps maintain the cable’s impedance and shielding effectiveness.

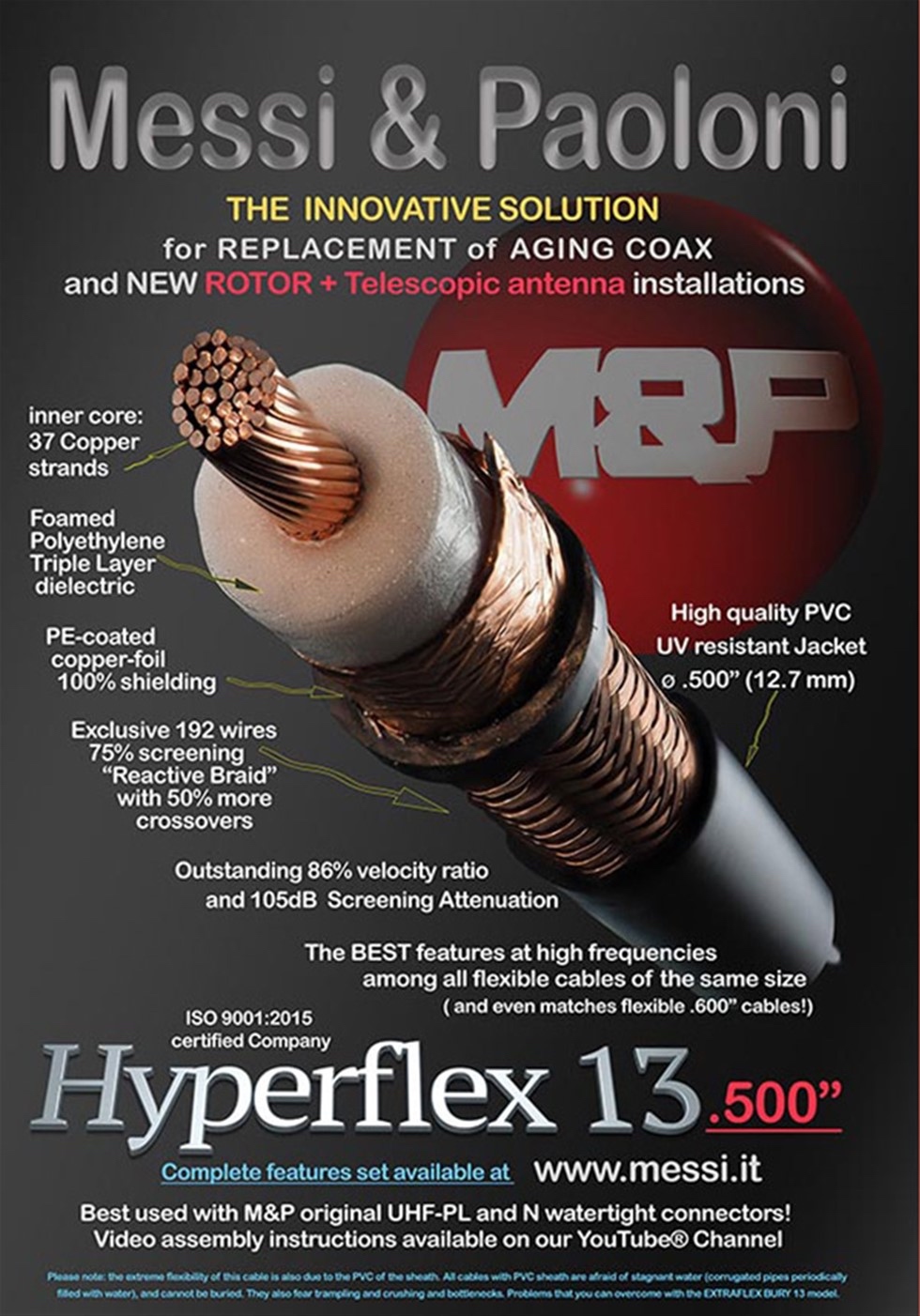

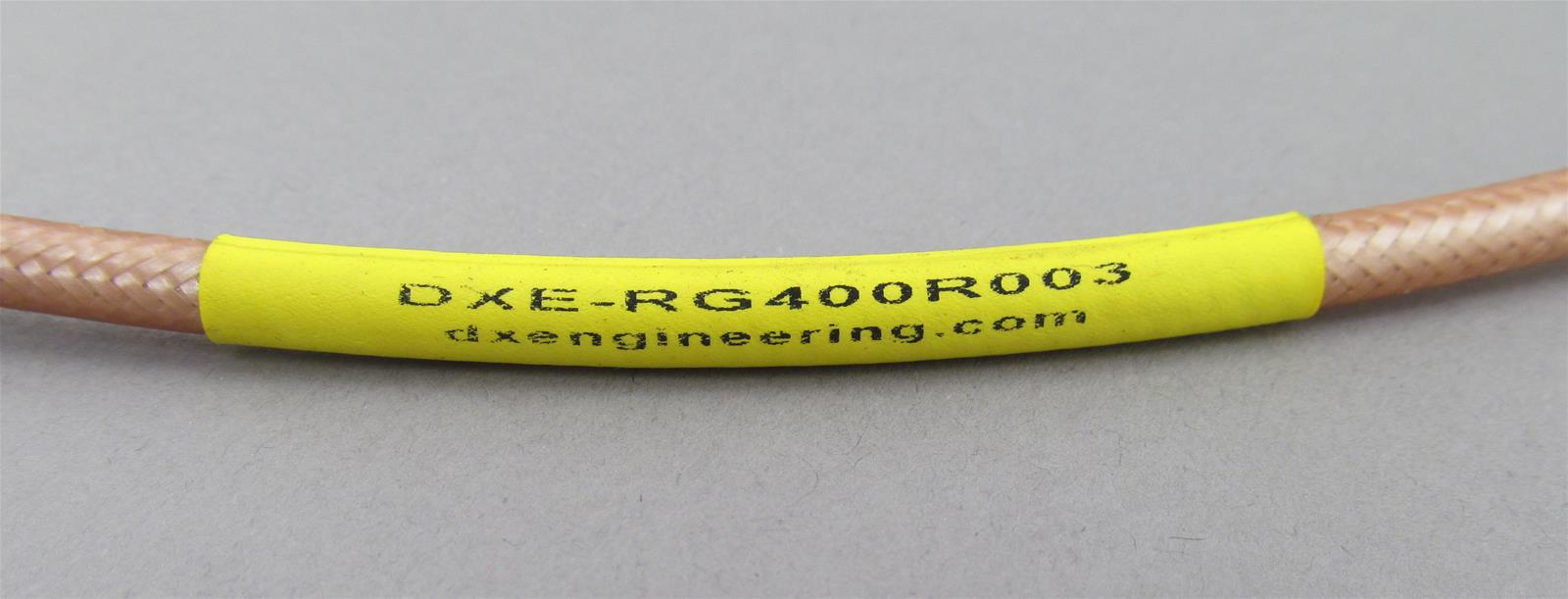

Why EVO Connectors? Because They’re Built to Last

Messi & Paoloni’s EVO connectors offer several advantages that make them ideal for demanding RF applications, especially in high-performance contest environments like ours. Their design combines mechanical strength, precision tolerances and superior electrical performance, ensuring consistent results even under the most extreme operating conditions:

- High-power handling

- Extremely low insertion loss

- Superior shielding effectiveness

- Double moisture-sealed, rugged water-tight construction

Messi & Paoloni’s EVO series PL-259 connectors are anything but generic. They use a compression-fit design with both internal and external sealing gaskets, making them fully moisture-proof and watertight.

This might seem excessive for indoor use, but it’s not. Even in protected environments, ambient moisture and humidity can cause condensation on contact surfaces, oxidation, and worse, corrosion of the coaxial braid. That kind of degradation slowly eats away at performance. The EVO design prevents it entirely.

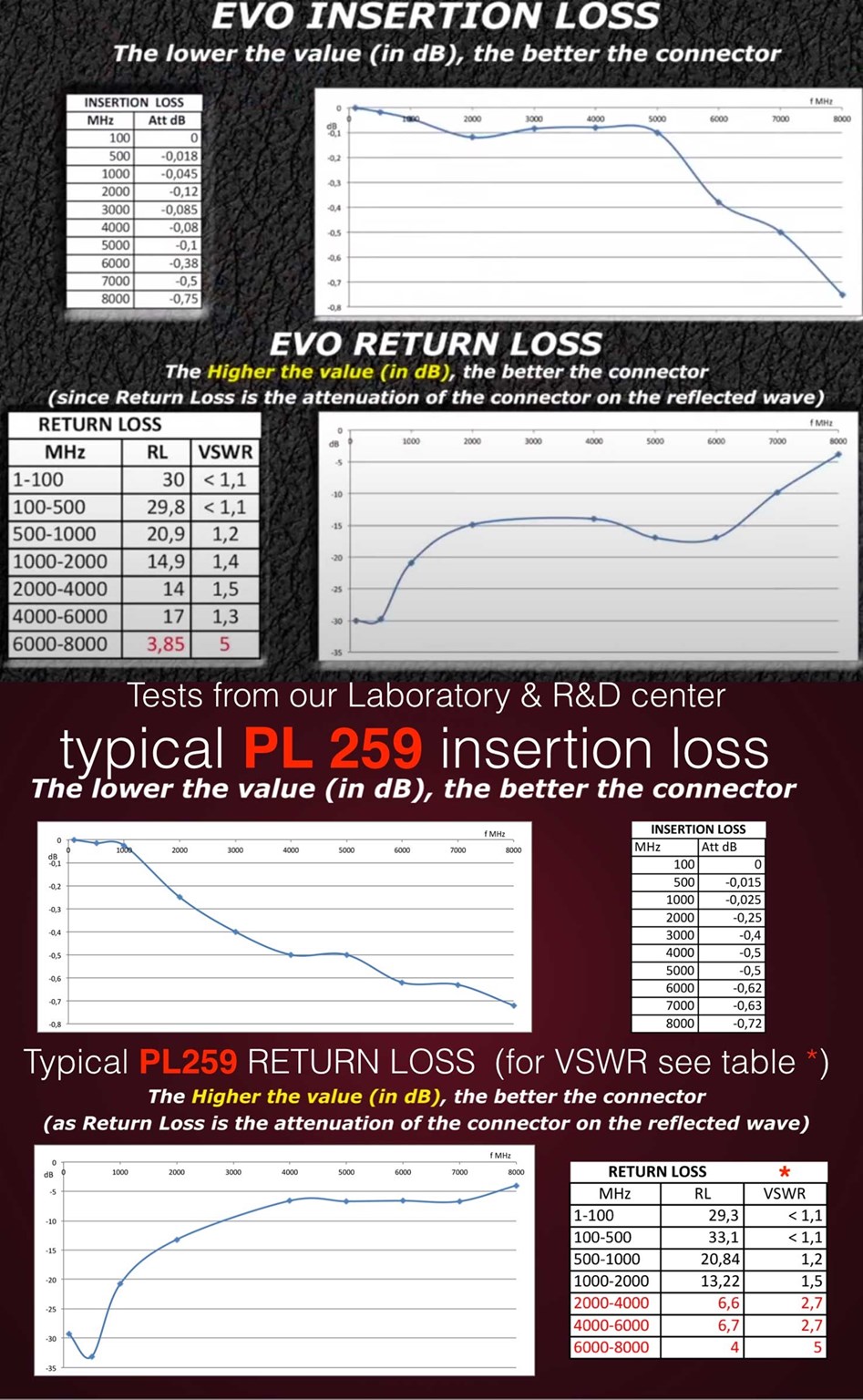

And their electrical performance is equally impressive:

- Insertion loss is negligible on HF and is nearly unmeasurable up to 100 MHz (<0.001dB), unlike conventional PL-259 connectors.

- Return loss exceeds 30 dB, which translates to VSWR better than 1.1:1

- Screening attenuation exceeds 105 dB, delivering outstanding shielding, dramatic noise suppression, and elimination of RF leakage

- Operational bandwidth extends up to 6000 MHz, far beyond the limit of typical PL‑259 connectors and on par with N-type connectors

- Advanced pin design avoids thermal damage by eliminating excess solder and heating stress, preserving the cable’s dielectric and electrical properties

- Improved mechanical tolerances eliminate solder burrs and make cable assembly easier and more precise

Poorly machined parts, low-grade plating, or inconsistent shielding contact can all introduce unpredictable losses.

These aren’t just specs, they’re verifiable performance figures that place the EVO line among the best in the industry and arguably best in the world.

Add to that their robust construction, excellent strain relief, and tight mechanical tolerances, and you have a connector built for both reliability and repeatability. Perfect for the demands of a busy contest station like SZ1A. For anyone rebuilding or upgrading RF patch cables, connector design matters more than most realize. Poorly machined parts, low-grade plating, or inconsistent shielding contact can all introduce unpredictable losses.

Professional-grade compression-fit connectors like the EVO series provide more stable and consistent RF performance across temperature changes and power cycles. Combined with proper installation and cable prep, they can significantly reduce long-term signal degradation.

See the video above for a detailed look at the design, features and engineering behind the M&P EVO connector

The example video above demonstrates the easy step-by-step procedure to install the M&P EVO PL-259 connector – M&P provides instructional videos for all of their connectors.

🔎 Partner Spotlight: Messi & Paoloni and FreeBytes

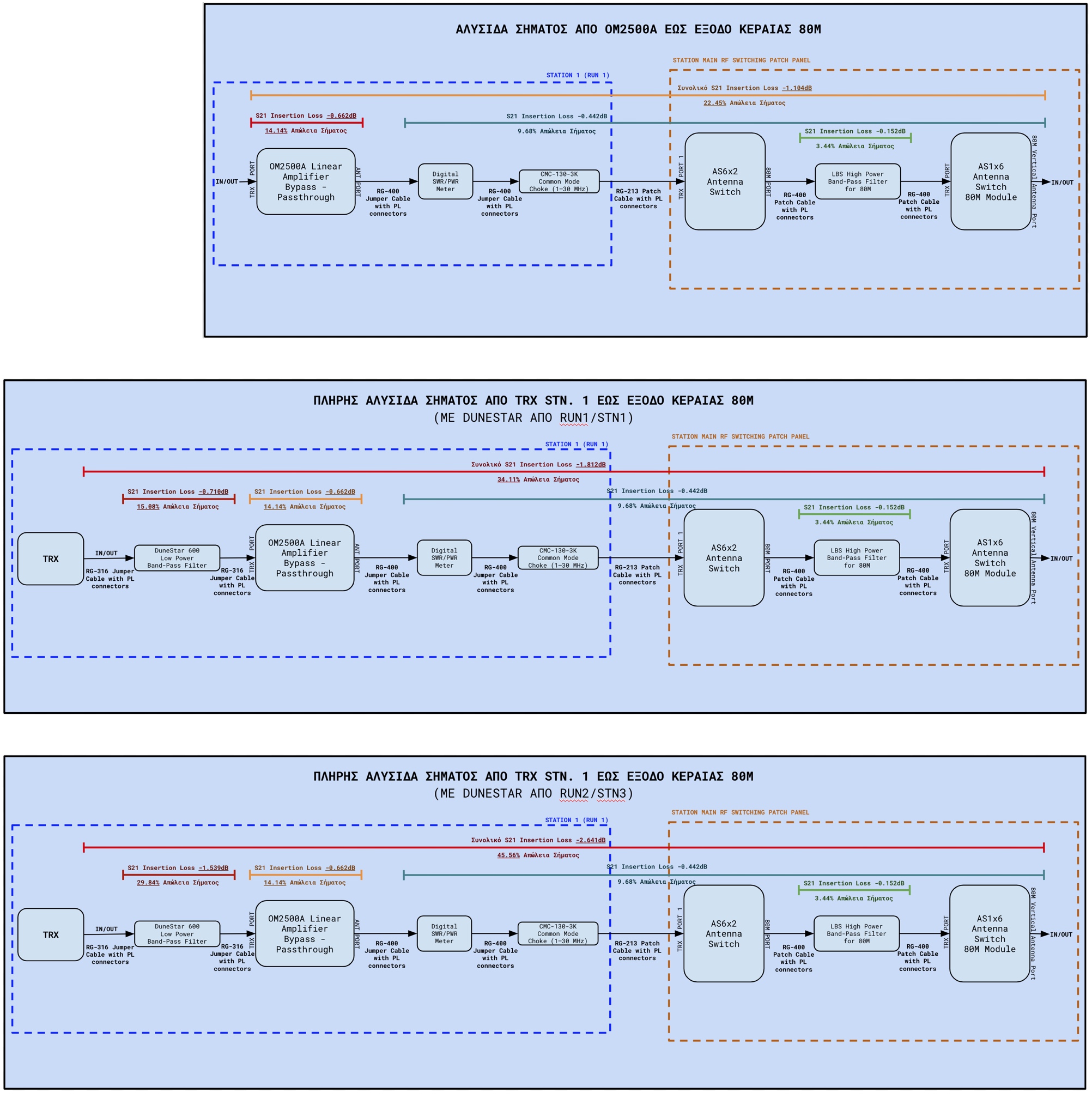

Messi & Paoloni is one of the most respected manufacturers of professional-grade coaxial cables and RF accessories. Based in Italy and family-run for over 40 years, the company has earned a stellar reputation for producing low-loss, high-performance coax like Hyperflex-13, Ultraflex-7, and Airborne-10, along with a full ecosystem of matching connectors and accessories.

Their products are trusted not only by amateur radio operators, but also by commercial, broadcast, and scientific users worldwide.

We’ve used M&P coax extensively at SZ1A, and many of our members rely on it in their own stations. Quality and performance consistently exceed expectations. With the EVO connector series, Messi & Paoloni has extended that same level of excellence into the hardware domain — combining mechanical strength, RF efficiency, and thoughtful engineering in one complete solution.

But great products are only half the story.

We’re also grateful for the incredible support we received from FreeBytes, M&P’s official distributor in Greece. From the first email to delivery and follow-up, their service was personal, precise, and reliable. It’s worth mentioning that FreeBytes was one of the few vendors that truly understood the technical challenges of a multi-op, high-performance, contesting station. Their support felt more like a collaboration than a transaction. They worked with us closely, offered special pricing for the station, and helped us select exactly what we needed.

FreeBytes is Greece’s largest and most trusted amateur radio distributor, founded by Giannis Kontarinis (SV1EEZ). Their team operates a full ISO 9001-certified service lab, represents every major brand, and actively supports the amateur radio community. We’re proud to now call them an official sponsor of SZ1A.

If you’re serious about your station we recommend them without hesitation.

Why Optimization Matters

Optimizing an amateur radio station begins with understanding the RF signal chain.

In an amateur radio station, the RF signal chain refers to the complete path a radio frequency signal takes from the transceiver to the antenna and vice versa. This includes all intermediate components such as amplifiers, filters, switches, patch cables, lightning arrestors, transmission line and chokes. Each element in the chain plays a role in maintaining signal integrity, efficient power transfer, and overall station performance.

By measuring key parameters like insertion loss (S21), return loss (S11), and SWR, you can identify which components are underperforming and where signal is being lost.

Understanding these measurements is key to improving performance:

• Insertion Loss (S21): This tells you how much signal is lost as it passes through a component. Within the desired passband, lower values are better, since even small losses can add up across multiple stages. For unwanted signals outside the passband, such as harmonics, higher insertion loss is desirable, especially in filter and choke applications.

• Return Loss (S11): This measures how much signal is reflected back due to impedance mismatch. Higher values indicate better matching and less reflection, which improves power transfer and reduces the risk of unwanted signal artifacts. In filter applications, lower return loss for out-of-band or unwanted signals can be beneficial, as it may indicate that these signals are being reflected rather than passed through.

• SWR (Standing Wave Ratio): Closely related to return loss, SWR shows how efficiently power is transferred from one stage to the next or to the load (usually the antenna). A lower SWR means more power reaches its destination instead of being reflected and bouncing back into the system.

Optimize everything. Because in serious contesting, every weak link matters

Modern tools have made this kind of testing accessible to every ham. The NanoVNA, which costs around $50, can measure S21, S11, and SWR across a wide frequency range with surprising accuracy. It can help identify hidden losses in connectors, jumpers, filters, amplifiers, chokes, switches, coax runs, and other components in the signal chain.

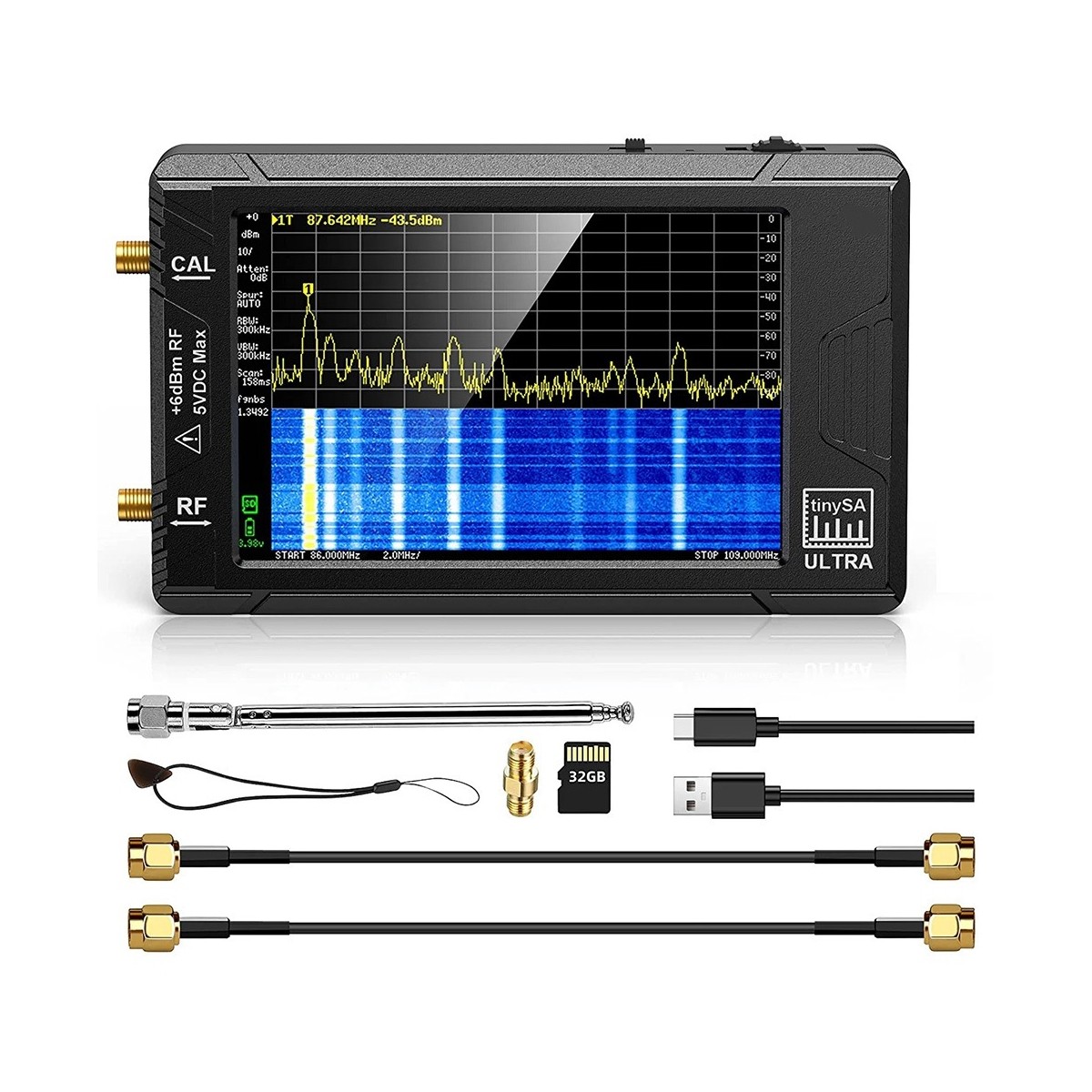

Another valuable tool for the modern radio amateur is the TinySA spectrum analyzer. Affordable and highly portable, it can scan a wide range of frequencies to display spurious signals, harmonics and unwanted noise. This makes it ideal for verifying transmitter cleanliness, measuring signal levels, and tracking down sources of interference.

Both the TinySA and the NanoVNA are now part of our toolkit at SZ1A and are used regularly to diagnose and troubleshoot performance issues, interference and other signal-related problems.

This level of visibility used to require expensive lab equipment. Today, with the right measurements and a bit of care, anyone can troubleshoot, validate, and improve their station’s performance in a measurable way.

In high-performance contesting, every fraction of a dB counts. Poor connectors may seem like a minor issue, but they can quietly degrade signal integrity, waste transmitter power, and reduce received signal levels, ultimately costing us contacts, points, and multipliers.

That’s why we now test every jumper with the NanoVNA before putting it into service. Gradually, as we install these new connectors, we’ll be bringing each link in the chain up to the standard that our station — and the level of competition we face — demands.

We’re firm believers in one simple principle: optimize everything.

Because in serious contesting, every weak link matters.

A Word of Thanks and a Contesting Philosophy

At SZ1A, we’ve always focused on performance. But performance is not just about big antennas, powerful amplifiers, expensive radios, or good propagation. It is about consistency. It is about knowing that every part of the RF signal path is doing exactly what it should. That confidence allows operators to focus fully on the contest, without second-guessing the equipment.

This project reminded us that even the smallest link in the chain can introduce measurable loss. Even a short jumper cable with a poorly made connector can degrade receive sensitivity, cause subtle impedance mismatches, or waste transmitter power. These faults often go unnoticed until they are measured. But once measured, they are impossible to ignore.

There was no glamorous upgrade here. No new tower. No new radios. Just connectors, tools, and a methodical process. What we have gained in return is a measurable improvement in performance and a renewed sense of trust in our station’s infrastructure.

For DX, you can get away with a mediocre station and operator. For contesting, everything must be excellent.

It is often said that the late, legendary John ON4UN, one of the most influential figures in low-band DXing and contesting, would often remark:

“For DX, you can get away with a mediocre station and operator. For contesting, everything must be excellent.”

It’s a simple truth that captures the higher standard contesting demands from both operator and station, where the state-of-the-art and striving for excellence matter more than ever.

And as many experienced contesters will earnestly tell you, a piece of common RF wisdom also holds true:

“To gain 1 dB, you need to spend 3 dB worth of money.”

In other words, squeezing out even the smallest performance improvements often requires disproportionate effort, precision, and investment. But in the world of competitive contesting, those small gains can make all the difference.

These are more than just clever quotes. They reflect a way of thinking that values quiet, persistent effort. Contesting performance is not just about major upgrades. It is about resolving small inefficiencies and removing every avoidable weakness, one component at a time.

That philosophy of incremental improvement is something we live by at SZ1A. It also shapes how we work with others, seeking out partners who share the same commitment to quality and reliability.

In the words of my dear friend and fellow engineering brother-at-arms, Kostas Stamatis SV1DPI, a long-time core member of the SZ1A team and contesting veteran, who recently expressed our gratitude to FreeBytes for their assistance in this project:

“We’re replacing every poor-quality or low-grade component in our station with better, more durable, and more precise materials. And for us, ‘quality’ means FreeBytes. We’re truly grateful to have you by our side.”

That comment speaks to something deeper. Serious contest stations are not just about having good equipment. They rely on knowing that every cable, filter, and switch will perform exactly as expected, with no surprises.

Achieving that level of reliability requires proper components, careful assembly, and real measurement.

It also requires confidence in the people behind the equipment. You need manufacturers, distributors, and dealers who act as true partners, committed to quality, consistency, and supporting your station’s success over the long term.

So what is the bottom line?

We cannot control solar activity. We cannot control the weather, and we certainly cannot control the competition.

But we can control what happens between the transceiver and the antenna. That is where the battle is won or lost. Every decibel matters. Every weak link matters. And every resolved issue brings us closer to the station we want to be.

We cannot control solar activity. We cannot control the weather, and we certainly cannot control the competition. But we can control what happens between the transceiver and the antenna.

📡 Onward and upward, with cleaner signals, better gear, and fewer decibels lost along the way.

The improvements we make today become the foundation for even greater performance tomorrow. Wishing you strong signals, solid contacts, and success in improving and optimizing your station.

Enjoy the engineering journey, and happy contesting.

73 and good DX to all,

Andy SV1DKD – Radio Amateur Association of Western Greece (SZ1A)